BioSpot®Workstations

- Nanoliter liquid handling with maximum flexibility

- Printing of lateral flow assays and biochips

- PipeJetTM non-contact printing technology

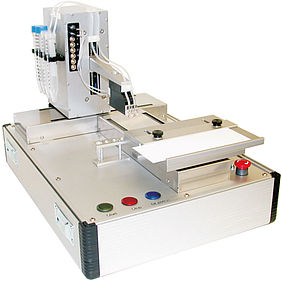

BioSpot® 160

The BioSpot® 160 workstation is a cost-efficient flexible tool for all liquid handling tasks in the small research lab. The PipeJetTM noncontact dispensing technology enables precise droplet transfer in the nanoliter to microliter range to all kinds of substrates. The BioSpot® 160 includes:

- workstation with 160 x 130 mm working area and flight case

- one PipeJetTM dispenser of your choice

- customization of the tray (slides, NC membranes etc. )

- PipeJetTM disposables and tubing

- BioSpot® Control Software

BioSpot® 160 offers a flexible stand-alone solution for all kinds of miniaturized liquid handling tasks like pipetting, spotting, printing and microfluidics. Its small size, the innovative non-contact printing technology and the competitive price make it ideal for decentralized use, saving time and trouble for laboratory staff and scientists.

Features

- Positioning precision ± 50µm TM

- Control of up to 8 PipeJetTM and 2 solenoid valves

- Single droplet size 5nl to 100 nl (depending on dispenser)

- Move and dispense function for drawing of lines

- Bitmap dispense for digital printing with low resolution

Optional upgrades:

- Syringe pump for aspirate & dispense

- Camera for aligned dispensing or stroboscopic droplet imaging

- Pressure controlled reservoir for highest accuracy

Specifications

- Dimensions: 432 mm x 330 mm x 346 mm

- Weight: 19 kg

- Software: Windows® compatible

- Electrical: 90 - 250 V @ 50 / 60 Hz, USB 2.0

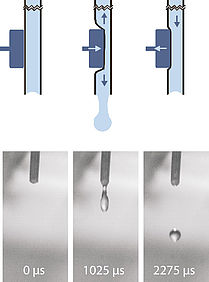

PipeJetTM technology

The PipeJetTM technology enables the contact-free dosage of small amounts of liquids in the range from a few nanoliter up to some microliter. Key element of the technology is an elastic micro tube with an inner diameter of a few hundred microns that is squeezed by a piezo stack actuator. By this displacement the liquid is driven out through the end of the pipe as a free jet. Different pipe diameters can be used with the PipeJetTM, the larger the pipe the larger the dosage volume. Dispensing pipes are available in different lengths and diameters.

BioSpot® Workstations

BioSpot® workstations are precise liquid handling workstations for nano pipetting and spotting of all kinds of liquids. The flexible system concept enables the contact-free dosage of liquid droplets in the range from a few nanoliter up to some microliter for a large variety of applications. Due to the small footprint and the flexible hard- and software all BioSpots® are ideally suited for laboratory research. The robust hardware and easy handling makes them also first choice for small scale production of lateral flow assays or other diagnostic substrates.

BioSpot® workstations are available in different sizes of the working area:

- 160 x 130 mm BioSpot® 160

- 350 x 130 mm BioSpot® 350

- 600 x 260 mm BioSpot® 600

Customization of the working area is possible to host substrates like electronic chips, wafers, slides, microfluidic chips, tissue samples, NC membranes etc.

The BioSpot® can host up to 8 PipeJetTM dispenser modules that can be configured in different ways including type and number of pipes as well as volume range.

User-friendly & flexible

The easy-to-use BioSpot® control software can be run on any Windows® PC to generate arbitrary pipetting and dispensing sequences. Drawing of lines and printing of dots, arrays and even low resolution graphics is enabled by the bitmap import feature.

All BioSpot® workstations are open for customization of any kind: A camera for online optical quality control or stroboscopic imaging can be integrated as well as other dispensing technologies.

PipeJetTM dispensers

The dispenser modules driving the pipes can be arrayed at a pitch of 4.5 mm or 9 mm to form multi-channel heads. Depending on the configuration PipeJetTM modules can operate in aspirate and dispense mode or as bulk reagent dispensers.

BioSpot® Benefits

Applications

Life Science

- lateral flow assays

- microarrays

- micro well plates

- microfluidic chips

Industry

- coating of medical products

- adhesive dispensing

- pharma production

- materials research

- semiconductors

PipeJetTM tested liquids

- buffers & detergents

- DMSO & other solvents

- ethanol & methanol

- beads & cells

- oils & adhesives

- strong bases & acids

- ...

The new and innovative BioSpot® workstation family introduces unmatched advantages and nearly unlimited options for customization.The PipeJetTM non-contact technology provides unique benefits like highest precision for a wide range of liquids, easy handling as well as robust materials and performance. Due to these unique features, the precise and highly reliable mechanics and the easy-to-use software, BioSpot® workstations are first choice for miniaturized liquid handling in research and production.

Precision & accuracy

The PipeJetTM technology features excellent accuracy and reproducibility of less than 3% CV for typical liquids at dosage volumes of 50 nl. Combined with the precise BioSpot® positioning stages spots can be printed with a reproducibility of 50 µm.

Robust performance

Due to the simple concept and the rugged materials the PipeJetTM dispensers are robust against clogging and all kinds of aggressive liquids.

Suited for difficult liquids

The valveless PipeJetTM technology enables the dosage of cells, beads, particles and higher viscous liquids, proven in many application examples.

Flexible & extendable

The flexible software supports all functions of the BioSpot®. Control is not limited to predefined functions or certain substrates (e.g. well plates). Extending the BioSpot® with additional dispensers or a camera is easily done anytime.

Customizable

BioSpot® workstations are fully customizable in terms of dispenser configuration, hardware and software.

Certified materials

All parts being in contact with the liquids are chemically inert and made from USP class VI certified materials. PipeJetTM tubes can be washed, plasma treated and sterilized.